Concept

The overall SteamBio concept is to create a commercially viable platform that can stabilise biomass materials close to source for subsequent biochemical and bioenergy uses. The platform will be scalable enabling both mobile deployment according to seasonal demands and fixed location for high volume throughputs.

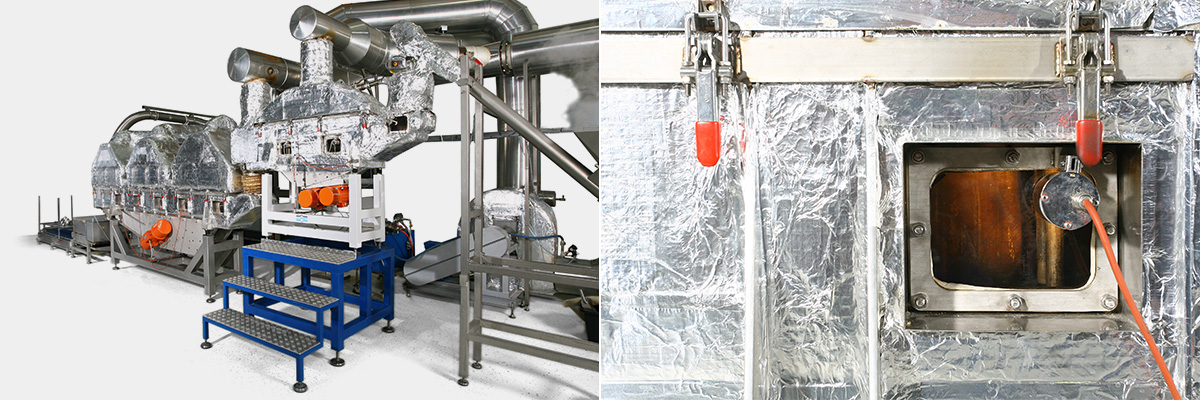

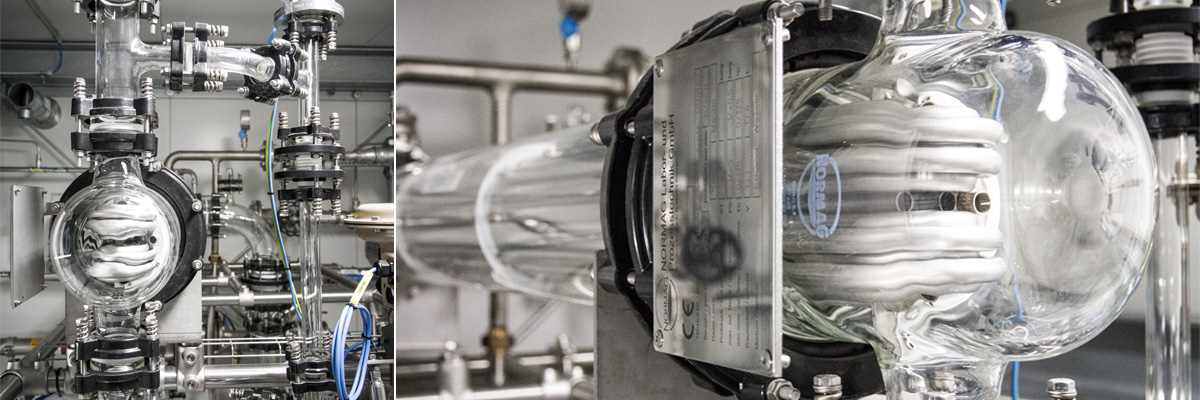

The core enabling technology is Superheated Steam Processing. Superheated Steam is an efficient heat transfer medium implemented at industrial scales in drying applications. It has been proven at pilot scales to torrefy assorted biomass materials into hydrophobic and grindable solids with value-added volatile compounds as a side stream. The continuous Superheated Steam Processing technology platform in SteamBio is scalable and has been proven technically at industrial scales with temperatures up to and in excess of 300°C.

SteamBio overcomes many of the limitations of existing torrefaction approaches with all outputs being clean and uncontaminated by flue gases enabling maximum value recovery and minimal environmental impacts.

Project Status – January 2018

Following successful commissioning in Germany at the primary manufacturing site (Heckmann) the demonstration unit has been successfully transported to Spain, where it will soon be open for visitors until July 2018. The first demonstration site is at Duruelo de Sierra (Soria) 230km 2hrs / 45mins from Madrid. If you want to visit the site or test the outputs please contact us.

Project Status – December 2017

Commissioning complete

We are really pleased to announce that the SteamBio demonstration unit has just completed its second full commissioning run. The plant operated without any deviation for over 72 hours producing torrefied beech wood chip and biochemical rich condensate streams. Once final inspection is complete we it will be shipped to Spain where it is due to be open for visitors until July 2018. Feel free to contact us to arrange a visit in 2018.

Project Status – June 2016

SteamBio aims to provide an adaptable industrial process that allows the use of assorted agricultural and forestry residues as a flexible feedstock for biochemical and bioenergy use. Confidence in this project delivering to the market is high as it approaches its mid-term stage. This has been reflected by the project exploitation lead, Network New Europe Ltd incorporating Steam Bio Ltd as a new company which will be the primary vehicle for the commercial exploitation of the SteamBio project results.

Project Status – April 2016

SteamBio has already selected six different reference-materials that are abundant and available from European forestry and farming operations. A demonstration unit with a throughput of 500kg/hour is currently under design and construction and will be deployed at different rural locations by January 2017. If you want to see this unit in operation during 2017, please contact Huw Parry.